Bathroom design

Wall and floor cladding

The solution for smooth walls and even floors.

Bathroom design

Floor-level showers

JACKOBOARD®: The beauty of barrier-free shower elements.

Bathroom design

Niche-shelf-partition walls

JACKOBOARD®: Attractive shelves, matching partition walls and shower stalls.

Bathroom design

Seating

The art of customized furnishings made easy.

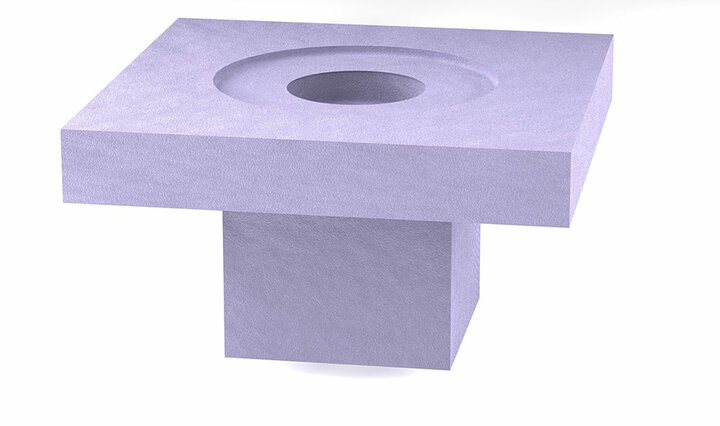

Bathroom design

Washstands

Suitable furnishing elements for every bathroom.

Roofing Solutions

Inverted roof in general

The thermal insulation for gravelled, greened, walkable and vehicle-accessible flat roofs.

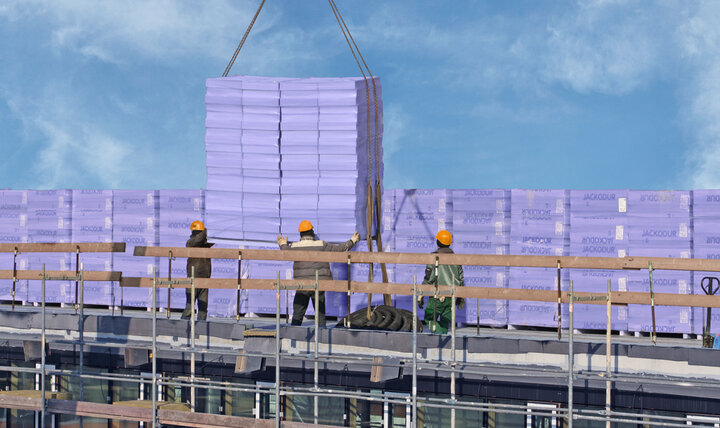

Roofing Solutions

Gravelled inverted roof

JACKODUR®: Durable insulation for functional flat roofs.

Roofing Solutions

Green inverted roof

JACKODUR: Sustainable insulated flat roof as the basis for a healthy urban climate.

Roofing Solutions

Vehicle-accessible inverted roof

JACKODUR inverted roof: The rooftop parking solution.

Roofing Solutions

Duo/Plus roof

Sustainable roof renovation for existing construction.

Over-rafter insulation

Reliable thermal bridge-free insulation in the pitched roof.

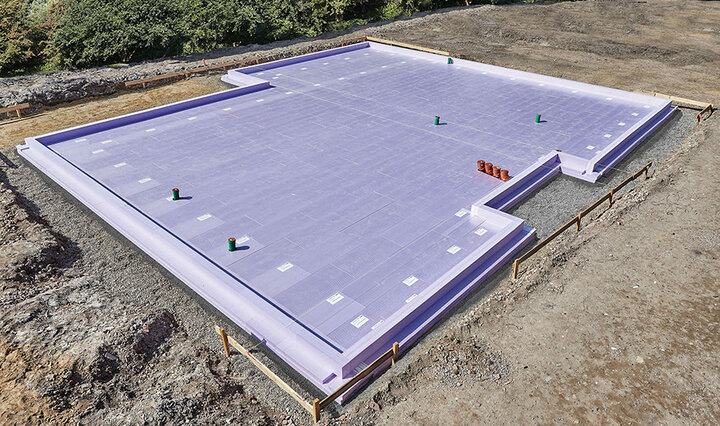

Building below ground level

Perimeter insulation of foundation slab

Building below ground level

JACKODUR® Atlas floor slab insulation system

Building below ground level

Perimeter of base-plate and foundations

Building below ground level

Perimeter insulation of basement retaining wall

Energy-efficient insulation for soil-contact structural elements.

Building above ground level

Top-storey ceiling insulation

Efficient renovation project insulation solution.

Building above ground level

Exterior insulation behind panelling

Thermal insulation with XPS insulation boards.

Building above ground level

Core insulation

Reliable insulation under severe weathering conditions.

Building above ground level

Window reveal

Thermal bridge-free insulation of window reveals with XPS.

Building above ground level

Plinth insulation under plaster

Optimal thermal and moisture protection in the perimeter area.

Building above ground level

Thermal bridge insulation

Save heating costs sustainably with JACKODUR®.

Building above ground level

Insulation under screed

The right choice for industrial screed insulation.

Industrial Applications

JACKODUR® XPS - versatile applications for industry

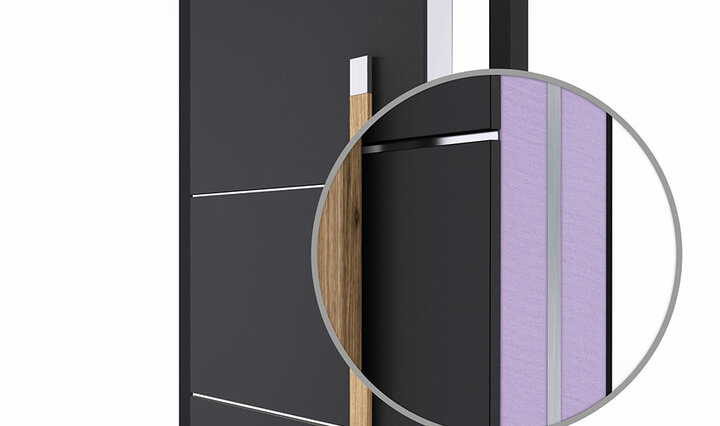

Industrial Applications

Sandwich elements

Industrial Applications

Door panels

Industrial Applications

Motorhomes

In the construction of recreational vehicles and camping cars, tolerances, stability and weight are crucial factors.

Industrial Applications

XPS cut to size

Industrial Applications

Refrigerated vehicles

Industrial Applications

Special-purpose vehicles

Individual solutions with JACKODUR® XPS for even the smallest production runs.